COLD FORGING

KOMATSU Cold Forging

The reason why Komatsu Kogyo has done research in cold forging is that there is much more benefit in this rather than in machining and grinding.

The Merits of Cold Forging which is the Deciding Factor in Cost-Cutting and Manufacturing Reform

Advantage

1

We can cut cost on materials.

The first merit is that we can reduce the cost of the materials we use. There is absolutely no loss in materials by cold forging when performing compression molding in comparison with machining and grinding materials. This also leads to a more effective way of using iron.

Adventage

2

This method is exceptionally fast.

There is speed in the manufacturing process. While the time in metal machining is measured in minutes, cold forging speed is measured in seconds. Naturally when the productivity speed increases, it becomes cost effective.

Adventage

3

Its adaptability to all shapes.

This third advantage is the ability to adapt to different shapes. Cold forging makes it possible to cut even the most difficult shapes. The end product is of high quality and there is no need to smooth off the rough edges because there are none. In this way we save money.

Though there are advantages to this way of machining, there are also some problems. We here at Komatsu Kogyo have complied years of know-how experience in cold forging using our own original techniques. This know how is also the secret of why we are able to meet and satisfy our customers' high standards and demands.

The next generation of technology that will be brought about will come from a compilation of all that we have learned up to now.

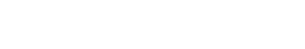

When projecting pins are being extruded from a material, the smaller the sectional area of the pin in relation to that of the material, (or, in other words, the larger the ratio by which the sectional area decreases) and the taller the height of the pins, the more skill is required. In order to alleviate these two problems, Komatsu Kogyo has raised itself to the challenge with higher technology.

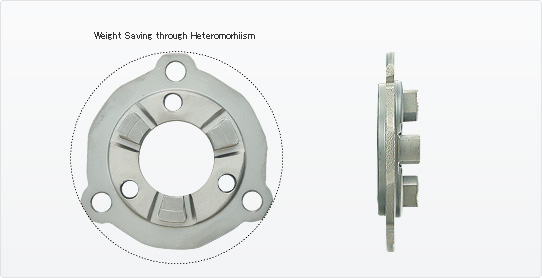

Komatsu Kogyo can take shapes that have normally been fabricated using hot forging or a composite forging that involves both hot and cold forging, and fabricate them using cold forging alone. Placing importance on speed production, Six Holes can be punched in six locations at the same time. In addition, we have been successful in weight saving through various forms.